BIOGAS PURIFICATION UNIT

Biogas is a useful source of energy, containing 40–70% of methane depending on its source.

It is a renewable source of energy. It does not compete with food chains, and in many cases, it can complement them. Most importantly, biogas can be produced in any country. These are major advantages, placing bio methane as an important sustainable source of energy and fuels.

Biogas can be locally used with very little pre-treatments to produce energy and heat. Pollutants like siloxanes, ammonia, and H2S should be ideally removed before burning biogas. When the amount of available biogas exceeds the local needs, the energy contained in biogas can be used remotely or as a fuel.

For these applications, the calorific power of biogas must be increased, and for that, carbon dioxide must be removed. The upgraded biogas is termed as bio methane.

Carbon dioxide removal from biogas is a bulk separation. According to the legislation of many countries, bio methane should meet the pipeline-quality specifications for natural gas, which limits the carbon dioxide content to 2–4%.

The biogas stream is also saturated with water. To reduce corrosion in pipelines and storage vessels, the water content should also be drastically reduced. The dew point of bio methane should be approximately −60 °C. There are many commercial technologies to upgrade biogas

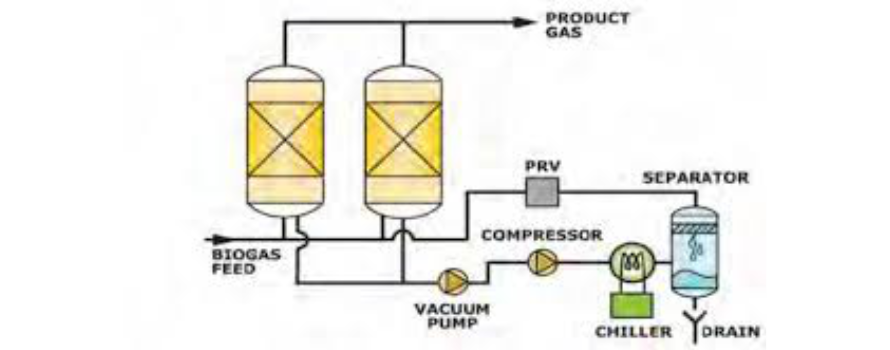

Process Diagram

PSA Principle

Pressure swing adsorption (PSA) is an interesting technology for biogas upgrading, due to compactness of the equipment, low energy requirements, low capital cost, and safety and simplicity of operation. Unfortunately, some shortcomings penalize its diffusion in comparison with other technologies; in particular, conventional PSA has a low methane recovery and cannot compete in this field with other processes such as amine scrubbing; furthermore, it produces an off gas stream with a significant methane content, which requires further treatment to avoid the emission of residual methane into the atmosphere. In this framework, this study focuses on the feasibility of a PSA based separation process able to obtain a bio methane stream suitable to be injected in the natural gas grid (CO2 <3% by volume) with a high methane recovery and an almost pure CO2 stream (CO2> 99%). The proposed process uses Zeolite 5A as adsorbent material in two PSA units; the biogas is fed to the first unit which produces bio methane; the off gas of the first unit is sent to a second PSA unit which separates carbon dioxide from a residual gas stream, recycled to the first to enhance methane recovery. A dynamic non-isothermal model, based on the linear driving force approximation, is employed to demonstrate the technological feasibility of the separation units and to assess the performance of the whole process. In particular a methane recovery greater than 99%.