HEAT LESS TYPE AIR DRYER

Operating Principle.

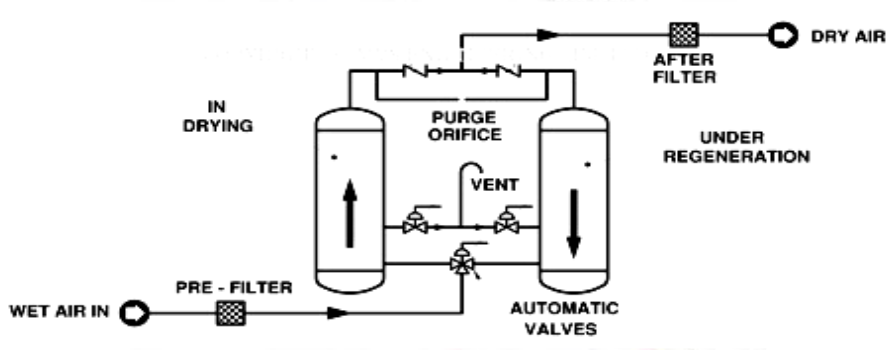

In Heatless Dryers, two vessels filled with desiccant are provided, which cycle automatically, producing Dry air continuously. In these units, wet air enters the bottom of one vessel and passes upwards through the desiccant bed where the moisture is adsorbed. The dry air comes out from the top. A small portion of Dry air is passed downward through the desiccant bed in the second vessel, which is under re-generation. Moisture laden purge air is then vented out to atmosphere. The purge loss is around 5% to 10% of the total air flow. At preset interval, the vessels changeover automatically, and Dry air is available continuously, without any surges.

Simple Design & Easy Operation.

This is the simplest type of Air Dryer with Activated Alumina / Molecular sieves drying agent. This design is virtually maintenance free, fully automatic, and requires no attention for years. Heatless type dryers do not require any heating for re-generation and therefore are very simple in design and maintenance free.

Low Investment & Low operating Cost.

Process Diagram for Air dryer.