HEAT OF COMPRESSION (HOC) TYPE AIR DRYER

HOC type dryer has nil operating cost. In this design hot air coming out from Air compressor discharge is used for regeneration of desiccant and so no external electric regeneration heating is required. This design easily produces dry air of (-) 40˚C Dew point.

Characteristics

Operating Principle

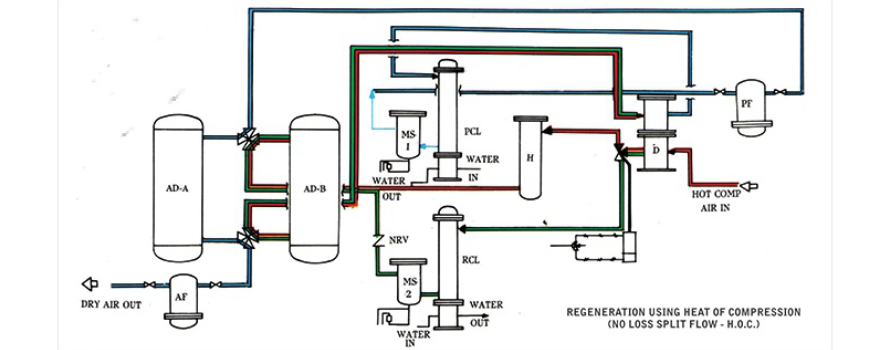

Compressed air, directly from Air compressor discharge is taken to Air dryer inlet through insulated pipelines, at 120˚Deg.C (minimum) temperature. This hot air is passed through one drying vessel where saturated desiccant is regenerated by this hot air. After picking up moisture from desiccant bed, the air is cooled in an intermediate cooler. Here moisture is condensed and removed by auto drain valve. Cooled to 40˚C, this air passes through the second drying vessel where moisture gets adsorbed and dry air comes out. Cycle time is 4 hours regeneration and 4 hours drying. After 4 hours the changeover of vessels takes place automatically. In regeneration cycle heating of the bed is for 2 hours, and thereafter the bed is cooled by dry air. After bed cooling, dry air is again cooled to 40˚C in another cooler and delivered as Dry air at 40˚C temp.

Process Diagram for HOC Type Air dryer