PSA OXYGEN GAS PLANT

PSA Principle

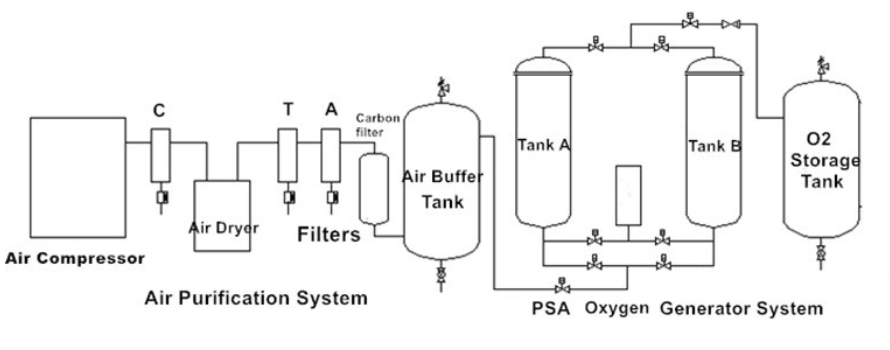

This process consists of 2 vessels filled with Zeolite Molecular Sieves and Activated Alumina. Clean compressed air at 25 Deg. ° C temperatures is passed through one vessel and oxygen comes out as product gas. The exhaust gas (Nitrogen) is discharged back into atmosphere. Upon saturation of the Zeolite Molecular Sieves bed, the process switches Oxygen generation to the other bed by automatic valves, while allowing the saturated bed to undergo regeneration by depressurization and purging to atmospheric pressure. Thus 2-vessels keep cycling alternately in Oxygen production and regeneration ensuring Oxygen gas is continuously available to your process.

Process Diagram

Technology CarboTech AC GmbH (Germany)

This is Molecular sieves Technology to produce low cost Oxygen from Air. Azote Eng. Company has long experience and know-how in Design and Manufacturing of such plants. Molecular sieves remove moisture and Nitrogen from Air. So up to 95% purity dry Oxygen gas is produced. We offer 2 designs- PSA and VPSA.

Continuous supply and guaranteed purity

When you install the PSA Oxygen Gas plant on-site, you are in control of your Oxygen supply. If you are currently using cylinders, then there is always dependence on your suppliers and there is no guarantee of the purity of Oxygen being supplied. With PSA system, you can be sure of the purity of Oxygen with the included Oxygen purity analyzer.

One of the most commonly asked question and confusing aspect of purity is when one talks about purity in terms of PPM level and another in Percent Level. So we have prepared a useful converter tool and also a printable chart for your use.